4 Steps of Maintaining Edgebander Edge Banding Machine

Every machine need to adjust and maintain for their best performance. Edgebanding machine contains the processes of: pre-milling, spray anti-glue coating agent, preheating of the plate, pressure sealing and cutting, front and rear cutting and roughing up and down, scratch repair and polishing, each process needs to check regularly in case of the worn of machine parts or computer system failure cause the damage of machine. So here are 4 projects you need to check on time:

1. Clean up the external of edgebanding machine regularly. First of all, we must clean the wood chips and various wood debris generated during the production process, to prevent the accumulating of wood chips which will cause the machine get stuck, affect the normal use of the edge banding machine. Secondly, clean the stains on the surface of the machine in time, to keep the edge banding machine tidy and prevent corrosion damage to the surface of the edgebanding machine.

2. Regular lubrication of the edge banding machine is very important. The bearings of the various parts should be lubricated regularly, and the proper lubricating oil must be selected.

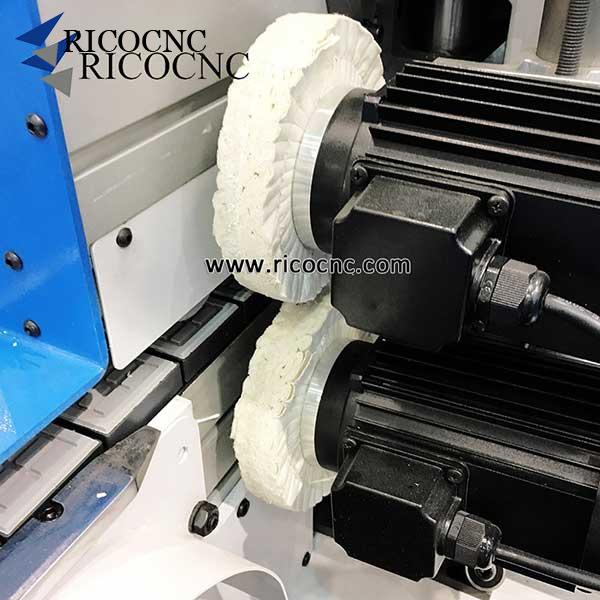

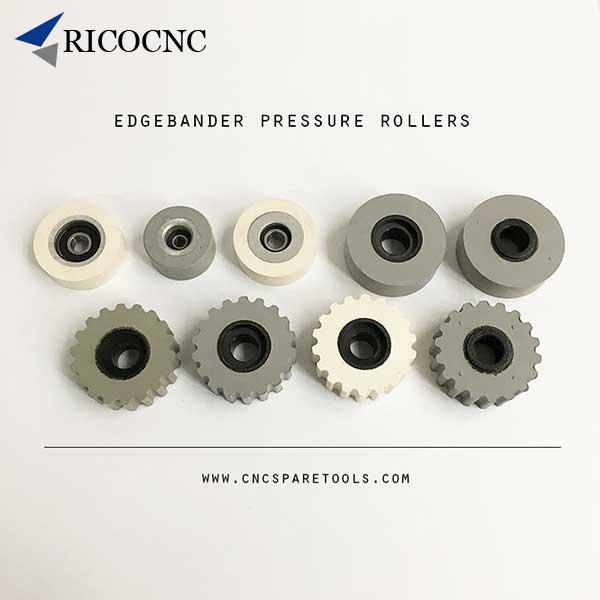

3. Regular inspections. Regularly check and maintain the edge banding machine. During the maintenance process, carefully check the wear and tear of the gears, bearings, pressure rollers, conveyor chain pads, support beam wheel, buffing wheel and other parts of the edge banding machine, and replace the worn parts in time.

4. The edge banding machine computer system maintenance. Today's edge banding machines are mostly connected to computers, so it can be automated by computer program. If there is a problem with the computer system, it will affect the normal use of the machine.

The guide rails of the edge banding machine should be cleaned every day. I recommend adding the 46th rail oil to the sliding surface, or the oil sealing hole. The edge banding machine oil water separator and oil cup is filled with low viscosity air compressor oil; add two-thirds of the oil cup. For the edge banding machine main drive motor, check the gear oil whether need to add every two months. The gears under the glue box of the edge banding machine should be inspected and cleaned every 40 hours, and filled with high viscosity grease.

The head rail part needs to be blown clean with an air gun every day, and then injected into the sewing machine oil or transformer oil, one or two times a day.

Here is the suggested checking list; you can adjust it based on your machine model:

|

No. |

Projects |

Project’s details |

Period |

1/1 |

2/1 |

|

1 |

Whole machine |

Clean external dust and wood chips |

1 Day |

|

|

|

2 |

Glue Shovel device |

Clean the cutting tools |

1 Day |

|

|

|

3 |

Pneumatic device |

Check condensate drain valve |

1 Day |

|

|

|

4 |

Gluing device |

Lubricating roller bearing |

2 Days |

|

|

|

5 |

Pre-milling device |

Check the cutting tools |

7 Days |

|

|

|

6 |

Check whether need replacement |

7 Days |

|

|

|

|

7 |

Front and rear cutting device |

Check linear guides and shock absorbers |

7 Days |

|

|

|

8 |

Refining device |

Check the sharpness of the tool, clean the motor and the hood |

7 Days |

|

|

|

9 |

front and rear tracking device |

Check tool sharpness and contour wheel |

7 Days |

|

|

|

10 |

Scraper device |

Check the sharpness of the tool |

7 Days |

|

|

|

11 |

Front and rear cutting device |

Linear guide lubrication |

15 Days |

|

|

|

12 |

Upper beam |

Check lubrication |

30 Days |

|

|

|

13 |

Upper beam pressure roller |

Check for wear |

30 Days |

|

|

|

14 |

Pre-milling device |

Guide rod lubrication |

30 Days |

|

|

|

15 |

Gluing device |

Cleaning the glue working parts |

30 Days |

|

|

|

16 |

Gluing device |

Check the glue level sensor |

30 Days |

|

|

|

17 |

Refining device |

Check lubrication of ball screw and movement parts |

30 Days |

|

|

|

18 |

front and rear tracking device |

Check lubrication of ball screw and linear guide |

30 Days |

|

|

|

19 |

Scraper device |

Check lubrication of movement parts |

30 Days |

|

|

|

20 |

Glue Shovel device |

Check lubrication of movement parts |

30 Days |

|

|

|

21 |

Polishing device |

Check the wear of the polishing wheel |

30 Days |

|

|

|

22 |

Main drive motor |

check the gear oil is enough or not |

60 Days |

|

|

Contact: RicoCNC

Phone: 0086-13390848665

Tel: 0086-51268235075

Email: cncsale@ricocnc.com

Add: NO. 60, Weixin Road, Industrial Park, Suzhou, Jiangsu, China, 215000

online service

online service 0086-15264185266

0086-15264185266 cncsale@ricocnc.com

cncsale@ricocnc.com