The basic you need to know when you decide to get an edgebanding machine

Working steps of straight edge banding machine

(1) Pre-milling: Pre-milling is to prevent the edge of the workpiece is not smooth enough for gluing the edge. If the board has slight chips or extra glue on the edge of the resealed board, it can be milled off according to the quality of the product, I mm a time can be milled at most.

(2) Spray anti-glue coating agent: anti-glue coating agent is also called separating agent. Spray it on the upper and lower ends of the plate edge before gluing, to prevent the glue from sticking to the surface of the plate during sealing. Also has the function of cleaning.

(3) Preheating of the plate: For the edge sealing process, the temperature is an important factor, and the temperature of the environment, the workpiece, and the hot melt glue should be controlled very well. The bonding temperature of EVA hot melt glue is usually around 150 °C. If the workpiece temperature is too low, the temperature of the hot melt glue will decrease rapidly after coating, which will affect the bonding strength of the edge band. It is therefore necessary to preheat the plate, especially in winter. Infrared illumination is generally used to achieve the effect of preheating.

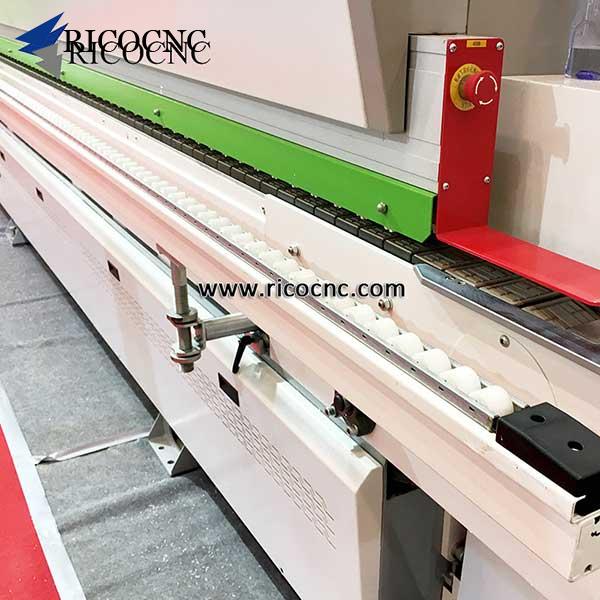

(4) Pressure sealing and cutting: After the board is preheated, the glue is applied to the edge by the glue coating device, and the pressure roller sends the edge strip to the edge of the plate, and then automatically cuts off.

(5) Front and rear cutting and roughing up and down: the plate is sent to the front and rear cutting device through the conveyor belt. For the cabinet, partition and other parts of the furniture, the thin edge banding (usually 0.4mm) is used for roughing up and down. The knife can directly process the edge band to the processing amount, eliminating the need for upper and lower finishing; the furniture door panel, panel and other components are mostly thick edge banding (usually 3mm), the edge has 2 or 3mm round corners, up and down must be refined after roughing.

(6) Scratch repair and polishing: Scratch repair is to use the scraper device to remove the milling marks on the edge of the edge band to make it more fused with the face of the plate. Finally, the plate removes residual hot melt glue and separating agent through the polishing unit.

The edge sealing process and process parameters of different kinds of workpieces are different. This requires adjusting the tool, air pressure, etc. according to the product requirements. The type and specifications of the edge banding material, the type of hot melt glue and the temperature of the environment are also important factors to consider. Process parameters such as temperature and feed rate. Therefore, in the actual production process, the edge banding machine should be adjusted according to the specific conditions.

Woodworking edgebanding is not complicated, just a few simple steps, but focusing on production efficiency and quality, you need to have a step-by-step production habit. Woodworking edgebanding has its correct operating procedures. The reason why each step of the whole operation exists can be greatly benefited from the use of the edge sealing, and the edge sealing production efficiency may be improved by understanding those processes.

Few tips about using edgebander machine

To make the door panels, especially the acrylic door panels, the most basic functions of an edgebanding machine is rough repair, tracking pre-milling, also front and rear cleaning must be added, so that the products have high-quality surface details, to make more high-level products.

Regarding the cleaning before and after, it is actually the glue removal device, the plate which has not been treated with the glue remover, and the plate which has been treated with the glue remover. The results are really different; especially the acrylic door panel and the cabinet edge seal. So don't remove these steps if you have sufficient funds.

The most useless functions of an automatic edge banding machine are: flat scraping and pneumatic adjusting knife. Some people want to have an edgebanding machine without the need of manual adjustment of cutting tools, only by pneumatic tuning knife or automatic knife adjustment, this kind of machine doesn’t exist, you still have to adjust those cutting tools manually for the best performance.

For your reference, here are some essential features of an edgebanding machine for cabinet and door making.

For cabinet making: Gluing, pressing, cutting, aligning, scraping, polishing, cleaning before and after, roughing, refined, pre-milling

For door panel making: glued, pressed, cutting, aligning, scraped, polished, cleaning before and after, roughed, refined, contoured tracking

There are a few common problems may occur when using the edge banding machine:

1. During using, the edgebanding is not sealed well. In some cases, the glue cannot be spread in a smooth, regular and equal way.

(1) The amount of glue may not be adjusted well. You can try to adjust the amount of glue.

(2) The glue pot has not been cleaned up in time

(3) You can check whether the heating tube under the glue pot is broken.

These three situations are the most common to occur.

2. The function of the head cleaning is not working. In this case, you can check whether it is a problem of pneumatic components and switch of control. In this situation, you need to adjust the machine under the guidance of professionals.

3. The edge banding machine stops working automatically after a period of time. In this case, if you have not mishandled, normally is the main power supply has a problem, you can ask an electrician to check the wiring problem.

Hope this article can give you a basic understanding of an edgebanding machine. And a list of edgebander spare parts in stock is better to keep your edgebander running well.

Good luck to your woodwork!

Contact: RicoCNC

Phone: 0086-13390848665

Tel: 0086-51268235075

Email: cncsale@ricocnc.com

Add: NO. 60, Weixin Road, Industrial Park, Suzhou, Jiangsu, China, 215000

online service

online service 0086-15264185266

0086-15264185266 cncsale@ricocnc.com

cncsale@ricocnc.com