CNC working experience you need to learn when your CNC cutters are easily broken

CNC working experience you need to learn when your CNC cutters are easily broken

3 important characteristics help router bits hard to be damaged.

1, The blade material of CNC router bits must have adequate hardness to cut though the workpiece.

2, And during cutting or engraving, those processes will generate lots of heat, especially in high RPM (revolutions per minute) and feed rate (cutting speed). So to keep strong hardness under high temperature, to carry on the scheduled work, heat resistance of blade material is very important.

3, Toughness is also an essential feature of cutter’s blade, because cutting tools have to bear a lot of impact, good toughness will protect blade from collapsing and splitting.

3 important characteristics help router bits hard to be damaged.

1, The blade material of CNC router bits must have adequate hardness to cut though the workpiece.

2, And during cutting or engraving, those processes will generate lots of heat, especially in high RPM (revolutions per minute) and feed rate (cutting speed). So to keep strong hardness under high temperature, to carry on the scheduled work, heat resistance of blade material is very important.

3, Toughness is also an essential feature of cutter’s blade, because cutting tools have to bear a lot of impact, good toughness will protect blade from collapsing and splitting.

Two main reasons cause damaged on cutter’s blade:

1. Mechanical wear

Mechanical wear is caused by the friction between chips, machined surface and the front surface of the bit.

This kind of friction is the main reason to damage blade of router bits when the cutter’s temperature is not too high.

2. Wear caused by heat

The high temperature of cutters during the work will make bits lose their hardness, so is easy to cause abrasion of the overheat part.

Two main reasons cause damaged on cutter’s blade:

1. Mechanical wear

Mechanical wear is caused by the friction between chips, machined surface and the front surface of the bit.

This kind of friction is the main reason to damage blade of router bits when the cutter’s temperature is not too high.

2. Wear caused by heat

The high temperature of cutters during the work will make bits lose their hardness, so is easy to cause abrasion of the overheat part.

Other kinds of abrasion

Under the situation of high temperature, there may be an adhesion between the cutting tool and the workpiece material, and some of the tool material is carried away by the chips, causing the tool to wear.

Other kinds of abrasion

Under the situation of high temperature, there may be an adhesion between the cutting tool and the workpiece material, and some of the tool material is carried away by the chips, causing the tool to wear.

At higher temperatures, certain elements of the cutting tool material (such as tungsten, cobalt, titanium, etc.) will diffuse into the workpiece, which will change the chemical composition of the blade of cutter, and also reduce tool strength and wear resistance, causing the diffusion wear.

At higher temperatures, certain elements of the cutting tool material (such as tungsten, cobalt, titanium, etc.) will diffuse into the workpiece, which will change the chemical composition of the blade of cutter, and also reduce tool strength and wear resistance, causing the diffusion wear.

How to determine whether the cutter’s blade is damaged:

1. From the sound of cutting or engraving. Listen to the sound during working process, if the sound of cutting is unusual, compare with the working sound which the first time you use the bit.

2. To observe in the process, if there are intermittent random sparks coming out, indicating that the tool has worn, this bit need to sharpen or change according to the average life of the tool.

How to determine whether the cutter’s blade is damaged:

1. From the sound of cutting or engraving. Listen to the sound during working process, if the sound of cutting is unusual, compare with the working sound which the first time you use the bit.

2. To observe in the process, if there are intermittent random sparks coming out, indicating that the tool has worn, this bit need to sharpen or change according to the average life of the tool.

3. If you are cutting or engraving metal object, the chip color changes, means the working temperature increases, may cause by the abrasion of cutter.

4. Look at the shape of the iron chip, if chip are not curled properly and become more tiny and irregular. Those circumstances prove that the tool has worn out.

5. Look at the surface of the work piece, whether there are bright traces. Although there is no big change in the roughness and size of object, this shows the tool has worn out.

6. Listen to the sound when the processing vibration is intensified. If abnormal sound occurs, it means this tool is not sharp. And at this time, the working object is easily to be damaged.

7. Check the machine is over capacity or not. The abrasion of cutter’s blade will cause the machine over it capacity.

3. If you are cutting or engraving metal object, the chip color changes, means the working temperature increases, may cause by the abrasion of cutter.

4. Look at the shape of the iron chip, if chip are not curled properly and become more tiny and irregular. Those circumstances prove that the tool has worn out.

5. Look at the surface of the work piece, whether there are bright traces. Although there is no big change in the roughness and size of object, this shows the tool has worn out.

6. Listen to the sound when the processing vibration is intensified. If abnormal sound occurs, it means this tool is not sharp. And at this time, the working object is easily to be damaged.

7. Check the machine is over capacity or not. The abrasion of cutter’s blade will cause the machine over it capacity.

The solution of different kinds of cutter’s damage

1. Blade abrasion

Decrease the RPM and feed rate. If lower the PRM and feed rate still can’t solve your problem, choose a different tool. (You can leave a comment)

2. Blade is broken

Choose other cutters with better toughness, tungsten solid carbide can satisfy most woodworking situation; PDF cutter is even more qualified. (Do not use PDF cutter on particle board)

3. Cutter’s shape changed by high temperature

Decrease the cutting speed, and plunge rate (mm/r), or use different cutters which made of materials with more heat resistance.

The solution of different kinds of cutter’s damage

1. Blade abrasion

Decrease the RPM and feed rate. If lower the PRM and feed rate still can’t solve your problem, choose a different tool. (You can leave a comment)

2. Blade is broken

Choose other cutters with better toughness, tungsten solid carbide can satisfy most woodworking situation; PDF cutter is even more qualified. (Do not use PDF cutter on particle board)

3. Cutter’s shape changed by high temperature

Decrease the cutting speed, and plunge rate (mm/r), or use different cutters which made of materials with more heat resistance.

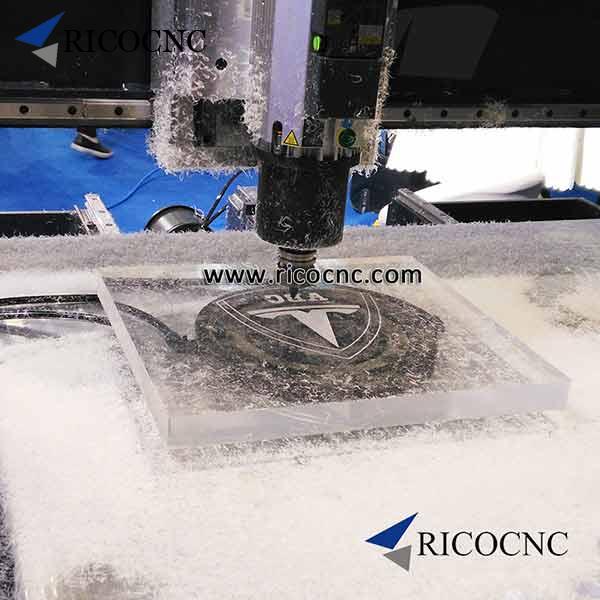

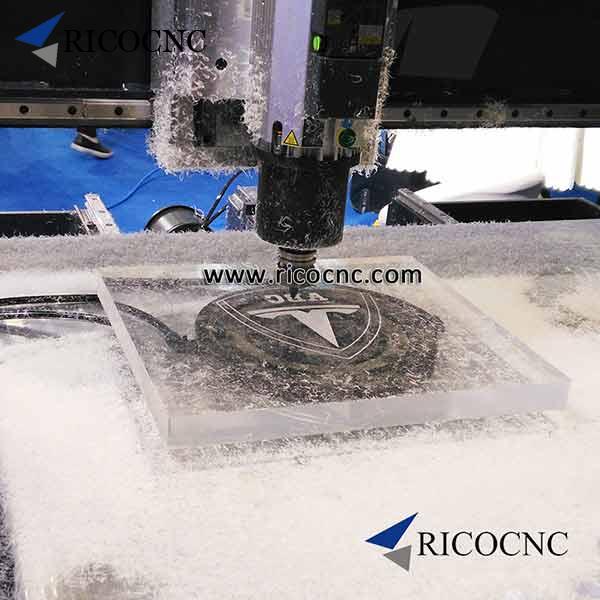

4. Blade crack caused by high temperature

This situation is happened on metal working. You need to use the cooling liquid properly, then decrease the cutting speed, feed rate and plunge rate. Or change to a router bits with coating. Coating can help the cutter resist more heat and also prevent corrosion.

4. Blade crack caused by high temperature

This situation is happened on metal working. You need to use the cooling liquid properly, then decrease the cutting speed, feed rate and plunge rate. Or change to a router bits with coating. Coating can help the cutter resist more heat and also prevent corrosion.

5. Hard to remove chips

Increase the cutting speed, RPM and plunge rate. Then use cooling liquid, make the blade sharper.

6. Cutter is broken or fracture

Use different cutters made of more tough material, then decrease the plunge rate and feed rate.

5. Hard to remove chips

Increase the cutting speed, RPM and plunge rate. Then use cooling liquid, make the blade sharper.

6. Cutter is broken or fracture

Use different cutters made of more tough material, then decrease the plunge rate and feed rate.

Those are my working experience during my CNC work, if you have other questions in CNC woodworking or metalworking, welcome to leave a comment or send me an e-mail. I will respond you as soon as possible. RicoCNC is a tool solution company for a large range of CNC tools.

Wish you good luck on your daily work.

online service

online service 0086-15264185266

0086-15264185266 cncsale@ricocnc.com

cncsale@ricocnc.com